Main page » Products » Shaker Mixers » dyna-MIX

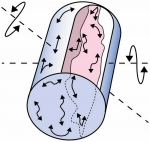

Three-dimensional shaker mixer

Where homogeneity of a mixture is concerned, high standards are increasingly demanded — and rightly so. The reproducibility of the mixing results is essential because any compromise regarding the productivity, appearance and quality of your product is unacceptable.

The three-dimensional shaker-mixer,

The principle of the patented

The

These areas are, for example, the homogenization of different dry components, the support of lengthy dissolution processes, or application or introduction of active or flavoring agents. Due to its great variety of designs, the

This shaker-mixer has proven itself in the following fields:

The

The clamping device for containers can be adapted to the actual circumstances, with your requirements and ideas having top priority.

With the PLC control system, highest flexibility is achieved. You can store up to nine mixing areas including the duration and rotation speed; the rotational speed can be infinitely adjusted using the two frequency-converters. The serial RS 232 printer interface permits documentation of the mixing process.

Due to the close collaboration with different companies we also have extensive know-how concerning the handling techniques before and after the mixing process. Benefit from the experience of our experts to find the optimum solution for your mixing processes.

Mixing in the existing containers therefore:

Time-saving, quick changing of the container due to:

High mixing homogeneity due to:

Easy program selection for different mixing areas due to:

A world-wide network with over 40 sales and service points provides support and advice. In addition to our comprehensive warehouse at our head office, our subsidiaries in Germany and France, as well as most of our sales and service points provide an extensive stock of spare parts for our customers. Our global network guarantees fast support at any time and therefore shorter downtimes.

| Type | CM 100 | CM 200 | CM 500 |

|---|---|---|---|

| Useful volume (l)* | 32 — 80 | 80 — 200 | 240 — 520 |

| Container volume (l)* | 40 — 100 | 10 — 250 | 300 — 650 |

| Max. load (kg) | 200 | 600 | 900 |

| Rotational speed (min-1)* | 0 — 30 | 0 — 30 | 0 — 25 |

| Power drive motor outer axis (kW) | 3 | 4 | 5,5 |

| Power drive motor inner axis (kW) | 1,1 | 1,5 | 2,2 |

| Total connected load requires (kW) | 5 | 7 | 11 |

| With lifting frame | no | no | yes |

| Min. load capacity per supporting point (kg) | 300 | 400 | 900 |

| Empty weight (kg) | 1400 | 1700 | 4400 |

| Dimensions (L × W × H) | 2450 × 1600 × 1500 | 2950 × 2100 × 1940 | 3900 × 2900 × 2300 |

CM 1000 upon request

*Depending on container dimensions and product density

Machine frame and covers made of stainless steel

Test the

© 2007 Tomášová Lea, s.r.o. - Industrial equipment | Phone: +420 466 650 876 | E-mail: office@tomasovalea.cz