Main page » Products » Dissolvers » Diamix 200 - 9000

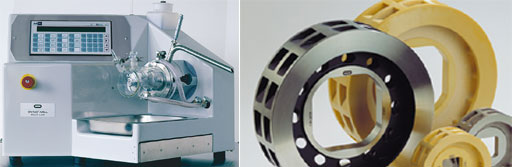

Diamix 200 - 9000

Diamix is the solution of today

The diamix is used for premixing and dispersion of low as well as high-viscous or thixotropic liquid products.

The enclosed construction makes it suitable for automation of charging and finishing process, and in addition it is very environment friendly. The combined construction of dissolver and anchor type agitator with spring-loaded scrapers reduces the production time as well as the consumption of power. At the same time the processing is optimised by the lifting/lowering and speed automatics.

Standard equipment

- Enclosed construction with connections and manhole in the top and centrally placed outlet in the bottom

- Container in stainless steel

- Dissolver unit with stirring shaft and telescopic shaft-protection tube as well as turbine plate with hub

- Anchor type agitator with spring-loaded scrapers, controlled by load-dependent frequency converter

- Lifting/lowering device

- Hydraulic pump system for lifting/lowering of the dissolver unit

- Control panel and PLC-controlled switchboard with modem

Additional equipment

- Dissolver motor controlled by frequency converter and speed automatics

- Motors and control panel in Ex-execution

- Acid-resistant execution

- Temperature monitoring

- Flushing device for inside cleaning

- Cooling/heating jacket

- Vacuum/pressure execution

- Stand for the control panel

- Special container sized

- Load cells

- Batch control

Advantages

- Excellent dispersion at low power consumption

- Energy saving (compared to a normal dissolver)

- High viscous products as well as heat-sensitive products can be produced without problems

- Smooth starting

- Suitable for automation

- Auto overload control

- Top mounted anchor mixer

- Scrapers made of Teflon

- Easy emptying of tank due to scraper empty mode as well as to the central placement of the outlet

- Effective cleaning device (automatic cycles)

- Electro-hydraulic lifting/lowering

- Easy to operate

- Easy maintenance

- Simple mechanical installation

- Vapour and dust reduced to a minimum

- Safe operation

Technical details

| Model | Motor / Controlboard | Motor power kW | Rotation speed rpm | Frequency converter | Net weight |

|---|

| N | Ex | Dissolver | Anchor agitator | Dissolver | Anchor agitator | | |

|---|

| 200 R | + | | 10 | 1.1 | 4300 | 34 | | 400 — 500 |

1500 R

1500 Ex

1500 REx

1500 RFEx | +

+

|

+

+ | 22

22

24

22 | 4,0

4,0

3,6

3,6 | 1500

500 — 1800

1500

500 — 1800 | 16

16

16

16 |

+

+ | 1500 — 2100 |

3000 R

3000 Ex

3000 REx

3000 RFEx | +

+

|

+

+ | 45

45

44

45 | 7,5

7,5

6,8

6,8 | 1500

500 — 1800

1500

500 — 1800 | 14

14

14

14 |

+

+ | 2800 — 3200 |

4500 R

4500 Ex

4500 REx

4500 RFEx |

+

+

|

+

+

| 55

55

58

55 | 11

11

10

10 |

1500

500 — 1500

1500

500 — 1500

| 11

11

11

11 |

+

+ | 3300 — 4000 |

6000 R

6000 Ex

6000 REx

6000 RFEx

| +

+

|

+

+ | 90

90

84

90 | 15

15

15

15 | 1500

500 — 1500

1500

500 — 1500 | 9

9

9

9 |

+

+

| 3800 — 4500 |

9000 R

9000 Ex

9000 REx

9000 RFEx | +

+

|

+

+ | 110

110

100

110 | 18,5

18,5

17,5

17,5 | 1500

500 — 1500

1500

500 — 1500 | 9

9

9

9 |

+

+ | 4500 — 5500 |